We supply a range of products and services designed to enhance the efficiency, reliability, and safety of electrical substations. These offerings can include:

We supply a range of products and services designed to enhance the efficiency, reliability, and safety of electrical substations. These offerings can include:

Automation Systems: This includes the hardware and software needed to control and monitor substation equipment. It often involves the installation and integration of SCADA (Supervisory Control and Data Acquisition) systems, and RTUs (Remote Terminal Units).

Communication Infrastructure: Solutions for reliable and secure data transmission between various components of the substation, including communication protocols like IEC 61850, fiber optics, and wireless communication systems.

Protection and Control Equipment: Devices such as protective relays, circuit breakers, and reclosers that safeguard electrical systems from faults and ensure proper operation.

Data Acquisition and Monitoring: Systems and tools for collecting and analyzing data from substation equipment to monitor performance, detect anomalies, and ensure optimal operation.

Integration Services: Expertise in integrating different automation components with existing substation infrastructure, including the adaptation of legacy systems and ensuring interoperability.

Maintenance and Support: Ongoing services for troubleshooting, repairing, and upgrading automation systems to ensure they continue to function effectively over time.

Consulting and Design Services: Assistance with the design and planning of substation automation systems, including system architecture, technology selection, and project management.

Training and Documentation: Providing training for substation personnel on the operation and maintenance of automation systems, as well as detailed documentation and manuals.

Overall, the goal of a service provider in this field is to deliver solutions that improve operational efficiency, reduce downtime, enhance safety, and support the overall reliability of the electrical power infrastructure.

A service provider for substation automation systems, specifically focusing on erection (installation and setup), typically handles a variety of tasks and responsibilities to ensure that automation systems are correctly installed and integrated into the substation infrastructure. Their services often include:

A service provider for substation automation systems, specifically focusing on erection (installation and setup), typically handles a variety of tasks and responsibilities to ensure that automation systems are correctly installed and integrated into the substation infrastructure. Their services often include:

Site Preparation: Assessing and preparing the physical site for the installation of automation equipment. This can involve clearing, leveling, and setting up the necessary infrastructure.

Installation of Equipment: Physically installing automation hardware, including control panels, communication devices, sensors, and actuators. This also includes mounting and wiring various components according to design specifications.

System Integration: Connecting and integrating automation systems with existing substation equipment and infrastructure. This includes ensuring compatibility between new and existing systems and integrating control and communication networks.

Configuration and Programming: Configuring and programming automation equipment such as PLCs, RTUs, and protective relays. This involves setting up parameters, developing control logic, and ensuring that the system performs as intended.

Testing and Commissioning: Conducting rigorous testing to verify that all components and systems are functioning correctly. This includes performing functional tests, verifying communication links, and ensuring system reliability and safety.

Calibration: Ensuring that all measurement and control devices are properly calibrated to provide accurate data and control signals.

Documentation and Reporting: Creating and providing detailed documentation on the installation process, system configurations, and testing results. This also includes updating as-built drawings and system manuals.

Training: Providing training for substation operators and maintenance staff on the newly installed automation systems. This training covers system operation, troubleshooting, and maintenance procedures.

Safety Compliance: Ensuring that all installation activities comply with relevant safety standards and regulations. This includes implementing safety protocols during the erection process and ensuring that the installed systems meet all safety requirements.

Post-Installation Support: Offering support and assistance after the installation is complete, including troubleshooting any issues that arise and providing ongoing maintenance if required.

The goal of these services is to ensure that the substation automation systems are installed correctly, integrated seamlessly into the existing infrastructure, and configured to meet the operational requirements of the substation.

The installation of substation automation systems involves a series of detailed and coordinated steps to ensure that all components are properly set up, integrated, and functional. Here's an elaboration on what the installation process typically entails:

The installation of substation automation systems involves a series of detailed and coordinated steps to ensure that all components are properly set up, integrated, and functional. Here's an elaboration on what the installation process typically entails:

1. Pre-Installation Planning

Site Assessment: Evaluate the site conditions, including space, access, and existing infrastructure. Determine any special requirements for the installation.

Design Review: Verify that the design specifications are accurate and complete. This includes reviewing electrical schematics, system layouts, and installation diagrams.

Resource Planning: Identify and procure the necessary tools, equipment, and materials for the installation. This includes coordinating with vendors and ensuring that all components are available.

2. Site Preparation

Clearing and Preparation: Prepare the physical site by clearing any obstructions and ensuring that the area is ready for the installation of equipment.

Foundation and Mounting: Install or prepare the foundations, mounting structures, and enclosures required for the automation equipment. This could include installing racks, cabinets, and panel supports.

3. Equipment Installation

Mounting: Securely mount automation hardware such as control panels, communication equipment, sensors, and actuators according to the design specifications.

Wiring: Perform electrical wiring and connections between different components. This includes power wiring, signal cables, and communication lines. Proper cable management and labeling are crucial for clarity and maintenance.

Connecting to Existing Systems: Integrate new equipment with the existing substation infrastructure. This involves connecting new systems to existing control systems, power sources, and communication networks.

4. System Integration

Network Setup: Configure and connect communication networks, including setting up communication protocols like IEC 61850. Ensure that all devices can communicate effectively with each other and with the central control system.

Control System Integration: Integrate the automation systems with the substation’s control systems. This includes configuring control logic and setting up data exchange between different components.

5. Configuration and Programming

Parameter Setting: Configure the parameters for each device according to the operational requirements. This includes setting up control parameters, thresholds, and operational modes.

Programming: Develop and load control programs into programmable devices such as PLCs and RTUs. This involves writing control logic and ensuring that it matches the design specifications.

6. Testing and Commissioning

Functional Testing: Perform comprehensive testing to ensure that each component operates correctly. This includes testing individual devices as well as the integrated system.

System Validation: Validate that the system performs as expected under various conditions. This involves simulating different scenarios and checking system responses.

Performance Testing: Ensure that the system meets performance criteria, including response times, accuracy, and reliability.

7. Calibration

Device Calibration: Calibrate measurement and control devices to ensure they provide accurate readings and control signals. This might involve adjusting sensors, relays, and other instruments.

8. Documentation and Reporting

Installation Records: Document the installation process, including details of equipment placement, wiring connections, and configuration settings.

As-Built Drawings: Update schematics and drawings to reflect the actual installation. This includes recording any deviations from the original design.

Testing Reports: Provide detailed reports on testing results, including any issues encountered and how they were resolved.

9. Training

Operator Training: Train substation personnel on how to operate and maintain the new automation systems. This includes instruction on system functionality, control interfaces, and troubleshooting procedures.

Maintenance Training: Provide training on routine maintenance tasks and procedures to ensure the long-term reliability of the system.

10. Safety Compliance

Safety Protocols: Ensure that all installation activities adhere to safety standards and regulations. Implement safety measures during installation to protect personnel and equipment.

Safety Checks: Conduct final safety checks to verify that all equipment is safely installed and that there are no hazards.

11. Post-Installation Support

Troubleshooting: Offer support for any issues that arise after installation. This may involve diagnostics, repairs, or adjustments.

Maintenance Services: Provide ongoing maintenance and support to ensure the system continues to operate efficiently and effectively.

The installation of substation automation systems is a complex process that requires careful planning, coordination, and execution to ensure that the system functions correctly and meets all operational requirements.

RTU and SCADA System Overview:

RTU (Remote Terminal Unit) and SCADA (Supervisory Control and Data Acquisition) are integral to substation automation systems. RTUs collect data from field devices and send it to SCADA systems, which provide a centralized interface for monitoring and control.

RTU (Remote Terminal Unit) and SCADA (Supervisory Control and Data Acquisition) are integral to substation automation systems. RTUs collect data from field devices and send it to SCADA systems, which provide a centralized interface for monitoring and control.

Commissioning Process:

Planning: Involves defining testing procedures, reviewing documentation, and preparing test equipment [2].

Installation Verification: Ensure proper installation and connectivity of RTUs and SCADA hardware [2].

Function Testing: Validate RTU and SCADA functionalities including signal integrity, data acquisition, and control commands [3].

Winch System Integration:

Winch used in substations require integration into the SCADA system for operational control and monitoring. Ensure that winch operations can be controlled and monitored via the SCADA interface [1].

Troubleshooting:

Precommissioning Checks: Verify system configurations and settings before full-scale commissioning [4].

Signal Testing: Utilize tools to simulate and test signals to ensure accurate data flow between RTUs and SCADA systems [5].

Issue Resolution: Address any faults or discrepancies identified during testing and ensure system functionality meets operational requirements [6].

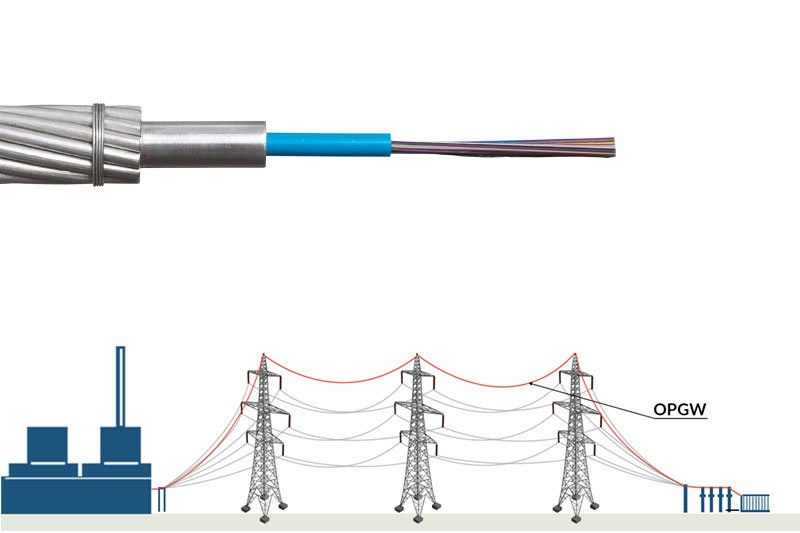

"OPGW cable stringing" refers to the process of installing Optical Ground Wire (OPGW) cables on transmission line towers. OPGW cables are a type of composite cable that serves a dual purpose: they function as a grounding wire for electrical protection and also contain optical fibers for high-speed data communication. Here’s a detailed breakdown of what the process entails:

"OPGW cable stringing" refers to the process of installing Optical Ground Wire (OPGW) cables on transmission line towers. OPGW cables are a type of composite cable that serves a dual purpose: they function as a grounding wire for electrical protection and also contain optical fibers for high-speed data communication. Here’s a detailed breakdown of what the process entails:

1. Preparation

Site Survey: Conduct a survey of the installation site to assess the existing infrastructure, plan the routing of the OPGW cables, and identify any potential challenges.

Equipment and Materials: Gather all necessary equipment, including the OPGW cables, stringing equipment (e.g., stringing blocks, tensioners, and pullers), safety gear, and tools for installation.

Safety Planning: Develop a safety plan that includes protocols for working at heights, electrical safety, and handling of the OPGW cables.

2. Cable Preparation

Cable Splicing: Prepare the ends of the OPGW cables for splicing. This involves stripping the cable to expose the optical fibers and metal conductors, and then splicing the fibers and connectors as needed.

Cable Handling: Ensure that the OPGW cables are handled carefully to avoid damage. They are typically stored on reels and need to be unwound properly during the stringing process.

3. Stringing Process

Stringing Equipment Setup: Set up stringing equipment such as stringing blocks (to guide the cable along the line), tensioners (to apply the correct tension), and pullers (to pull the cable through the towers).

Cable Installation:

Pulling: Use the pullers to pull the OPGW cable from one tower to the next. The tensioners help maintain the correct tension to prevent damage to the cable.

Guiding: Guide the cable through the stringing blocks and across the spans between towers.

Attachment: Secure the OPGW cable to the transmission line towers using appropriate hardware, such as clamps and fittings. Ensure that the cable is properly anchored and supported.

4. Cable Tensioning

Adjust Tension: After the cable is installed, adjust the tension to the specified levels. Proper tensioning is critical to ensure the cable’s performance and longevity, as well as to prevent mechanical stress that could damage the cable or the towers.

Checking: Inspect the cable installation for any signs of stress, sagging, or other issues. Ensure that the cable is evenly tensioned across all spans.

5. Finalization

Connections: Make final connections to any equipment or termination points, such as junction boxes or optical network units.

Testing: Test the optical fibers for signal integrity and communication performance. This involves checking the optical attenuation, signal loss, and data transmission rates.

Inspection: Conduct a final inspection to ensure that all aspects of the installation meet the required standards and specifications.

6. Documentation and Reporting

Documentation: Record all details of the installation process, including cable lengths, tension settings, and test results.

Reporting: Provide a report on the installation, including any issues encountered and how they were addressed.

Benefits of OPGW Cable

Dual Functionality: Combines grounding and data communication in one cable, reducing the need for separate grounding wires and communication cables.

Improved Communication: Provides a reliable means of high-speed data transmission for monitoring and control of the transmission network.

Enhanced Protection: Protects the transmission lines from lightning strikes and electrical faults while providing critical data communication.

In summary, OPGW cable stringing is a specialized process involving the careful installation of cables that serve both as electrical ground wires and data transmission lines. It requires precision and adherence to safety standards to ensure proper function and reliability of the transmission network.

Panel retrofitting refers to the process of upgrading or modifying existing electrical panels (or switchgear panels) to improve their performance, functionality, or safety. This often involves incorporating new technologies, replacing outdated components, or adapting the panel to meet modern standards and requirements. Here’s a detailed breakdown of what panel retrofitting typically involves:

Panel retrofitting refers to the process of upgrading or modifying existing electrical panels (or switchgear panels) to improve their performance, functionality, or safety. This often involves incorporating new technologies, replacing outdated components, or adapting the panel to meet modern standards and requirements. Here’s a detailed breakdown of what panel retrofitting typically involves:

1. Assessment and Planning

Initial Assessment: Evaluate the current state of the existing panel, including its components, functionality, and any issues or limitations. This involves inspecting the panel’s condition, reviewing its design, and understanding its role in the electrical system.

Requirements Analysis: Determine the specific needs for retrofitting, such as increasing capacity, enhancing protection features, or adding new functionalities. This includes identifying any regulatory or safety standards that need to be met.

Design and Planning: Develop a retrofitting plan that outlines the scope of work, including the components to be replaced or upgraded, the integration of new technologies, and the overall approach to the retrofit.

2. Component Replacement and Upgrade

Switchgear and Circuit Breakers: Replace outdated or underperforming switchgear and circuit breakers with modern, more reliable alternatives. This may include upgrading to higher-rated components or adding new protective features.

Instrumentation: Install new measurement and monitoring instruments, such as digital meters, sensors, and control interfaces, to provide better visibility into the panel’s operation and performance.

Communication Systems: Upgrade or add communication capabilities, such as integrating with SCADA (Supervisory Control and Data Acquisition) systems, for improved remote monitoring and control.

3. Technology Integration

Protection Relays: Replace old electromechanical relays with advanced digital protection relays that offer more precise fault detection, analysis, and communication capabilities.

Control Systems: Implement modern control systems, including programmable logic controllers (PLCs) or microprocessor-based controls, to enhance automation and functionality.

Energy Management: Incorporate energy management systems or software to optimize energy use, track consumption, and improve efficiency.

4. Safety and Compliance

Safety Enhancements: Upgrade safety features such as arc flash protection, interlocks, and alarm systems to meet current safety standards and protect personnel and equipment.

Regulatory Compliance: Ensure that all retrofitted components and systems comply with relevant electrical codes and industry regulations.

5. Installation and Testing

Installation: Implement the retrofitting plan by installing new components, wiring, and control systems. This may involve modifying the panel layout or enclosure to accommodate new equipment.

Testing: Perform thorough testing of the retrofitted panel to ensure that all components and systems function correctly. This includes verifying electrical connections, checking system performance, and conducting safety tests.

6. Documentation and Training

Documentation: Update panel documentation to reflect changes made during the retrofit. This includes revised schematics, operational manuals, and maintenance guides.

Training: Provide training for personnel on the new features and functionality of the retrofitted panel. This ensures that operators and maintenance staff are familiar with the upgraded system.

7. Post-Retrofit Support

Maintenance: Offer ongoing support and maintenance services to address any issues that arise after the retrofit. This includes troubleshooting, repairs, and periodic inspections.

Performance Monitoring: Monitor the performance of the retrofitted panel to ensure it continues to meet operational and safety requirements.

Benefits of Panel Retrofitting

Enhanced Functionality: Incorporates advanced technologies and features to improve the panel’s performance and capabilities.

Increased Reliability: Replaces outdated components with modern, more reliable ones, reducing the risk of failures and outages.

Improved Safety: Upgrades safety features to protect personnel and equipment, and ensures compliance with current safety standards.

Cost-Effective: Extends the life of existing equipment and infrastructure, potentially reducing the need for complete replacements.

Future-Proofing: Prepares the panel for future demands and technological advancements, making it more adaptable to changing requirements.

In summary, panel retrofitting is a strategic approach to modernize and improve existing electrical panels, enhancing their functionality, safety, and compliance with contemporary standards. It involves careful planning, component upgrades, technology integration, and thorough testing to ensure the panel meets current and future needs.

Offer ongoing support and maintenance services to address any issues that arise after the retrofit. This includes troubleshooting, repairs, and periodic inspections.

Offer ongoing support and maintenance services to address any issues that arise after the retrofit. This includes troubleshooting, repairs, and periodic inspections.

Performance Monitoring: Monitor the performance of the retrofitted panel to ensure it continues to meet operational and safety requirements.

Benefits of Panel Retrofitting

Enhanced Functionality: Incorporates advanced technologies and features to improve the panel’s performance and capabilities.

Increased Reliability: Replaces outdated components with modern, more reliable ones, reducing the risk of failures and outages.

Improved Safety: Upgrades safety features to protect personnel and equipment, and ensures compliance with current safety standards.

Cost-Effective: Extends the life of existing equipment and infrastructure, potentially reducing the need for complete replacements.

Future-Proofing: Prepares the panel for future demands and technological advancements, making it more adaptable to changing requirements.

In summary, panel retrofitting is a strategic approach to modernize and improve existing electrical panels, enhancing their functionality, safety, and compliance with contemporary standards. It involves careful planning, component upgrades, technology integration, and thorough testing to ensure the panel meets current and future needs.

Supply

Erection

Installation

Commissioning

OPGW cable stringing

Panel retrofitting

Project management

Man power supply

Verona, Plot no. 5A, Sector 10E, road Patil, Kalamboli, Navi Mumbai 410218